About Us

For over 30 years, MPS has supplied products and services to promote safety and efficiency in industry. All of our equipment is the highest quality, backed by product experts and dependable customer service. In the last decade, our focus has shifted to keeping our customers’ workforce safe and secure by providing top quality, innovative safety solutions, in addition to our roots in the mining and process industries.

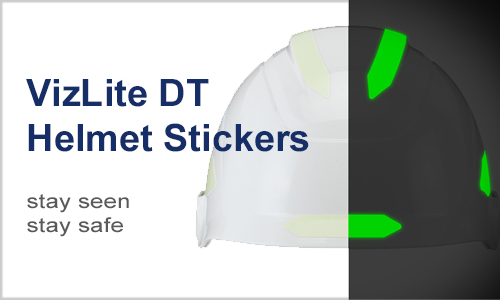

Our head protection solutions are unique to North America, comfortable and progressive, in order to protect our most important asset —it’s head protection for the 21st century. We provide reliable fire detection systems with instantaneous flame and spark recognition, and our industrial vibrators are quiet and lightweight enough to gently convey fragile vials, while strong enough to set concrete forms and unload railcars. Our mining and tunneling guidance lasers stand up to the rigors of underground environments for the long haul, while our palm-sized intrinsically safe anemometers provide mistake-free air flow readings, the most accurate in the mining industry.

With our innovative equipment and personal attention, we make industry safer and more efficient.